Mechanical Engineering Labs

Mechanical Workshop

The main objective of this course is to develop a machining skill in the dignity of labor, precision, and safety at the workplace, teamwork, and the development of the right attitude. This course also enhances the skill of measurements and improves the skills in basic engineering practices with hand tools and instruments which are commonly used in the basic workshop practice.

Fluid Mechanics and Machinery Laboratory

The purpose of this laboratory is to reinforce and enhance your understanding of the fundamentals of Fluid mechanics and Hydraulic machines. The experiments here are designed to demonstrate the applications of the basic fluid mechanics principles and to provide a more intuitive and physical understanding of the theory. The prime objective of this laboratory is to discuss and practice standard measurement techniques of fluid mechanics and their applications. It also includes the performance of various apparatus at different operating points. After completion of the laboratory, the students will be able to understand the concept of fluid machinery such as different types of turbines and pumps and various non-dimensional parameters applicable to hydraulic machines. The students will be able to verify Bernoulli’s Theorem and calibrate the venturi-meter, Orifice meter, Nozzle, Pitot tube, etc. The students will be able to characterize laminar, Turbulent flows and analyze the stability of floating bodies at the end of this laboratory class.

Elements of Solid Mechanics Laboratory

The objective of this Laboratory is to teach the students about the evaluation of different mechanical properties of metals viz. a) Limit of proportionality b) Elastic limit c) Yield strength d) Ultimate strength e) Young's modulus of elasticity f) Percentage elongation g) Percentage reduction etc. Furthermore, the Torsion test, Hardness Test, Izod & Charpy test, Compressive strength tests are also conducted under the laboratory. Pictorial views of some of the instruments are shown below:

Production Engineering Laboratory I

The objective of this course is to understand the working of machine tools such as lathe, shaper, planner, slotter, milling, hobbing, and grinding and to familiarize with the selection of suitable production processes for the manufacturing of the desired component. This course also reveals the basic concepts of NC and CNC machine tool programming and computer-aided part programming. Pictorial views of some of the instruments are shown below:

Production Engineering Laboratory II

The objective of this course is to understand the cutting forces, the average cutting temperature in machining processes under the different feed and speeds. The course is delineated particularly to understand chip formation mechanism and relevant matters (type, color & thickness) during different machining processes and evaluate the role of variation of cutting speed and feed on-chip reduction coefficient /cutting ratio and shear angle. Pictorial views of some of the instruments are shown below:

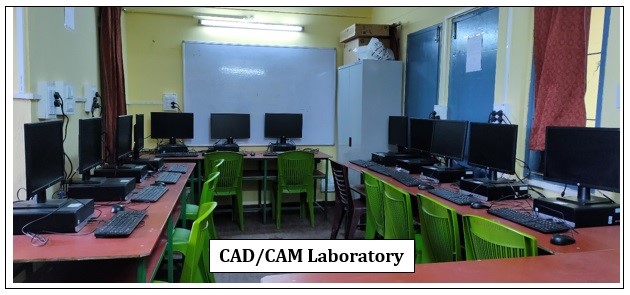

CAD/CAM Laboratory

CAD/CAM laboratory of the institute introduces various types of the design software which are very useful for design the various types of machine components. This laboratory provides the basic concepts of CAD. In this laboratory, students can develop 2D models and 3D models on CAD software (Solid Works), various 3D Models using basic Boolean operations: shell, sweep, revolve, loft, extrude, filleting, chamfer, splines, etc. To impart knowledge on manual part programming for CNC lathe and NC milling are the major objectives of this laboratory.

Drawing Laboratory

The objective of this Laboratory is to teach the students about the representation of elements of machine drawing, Introduction to Engineering Materials, Surface finishes, tolerances, sectional views, screw threads. Component drawings of bolts and nuts, locking devices, keys, and cotter joints, knuckle joints, riveted joints, shaft couplings, bearings, and pipe joints are also taught to the students. Furthermore, assembly drawing practice and drawing of the assembly of the stuffing box, pedestal bearing using the component drawings are being practiced by the students in this laboratory.

Metrology and Instrumentation Laboratory

The objectives of the Mechanical Measurements & Metrology lab are to demonstrate the theoretical concepts taught in Mechanical Measurements & Metrology and also to understand and use various measuring tools with calibration of various measuring devices. Thread profile measurement, usage of autocollimator, profile projector, surface roughness tester, thermal imaging device are being taught to the students. Pictorial views of some of the instruments are shown below:

Heat Transfer Laboratory

The heat transfer laboratory of the Institute is well equipped with modern instruments to strengthen the knowledge of students in this particular domain. Instruments of this laboratory are procured under the aegis of TEQIP-III of the Institute. This laboratory is aimed to equip the students with proper knowledge on Conductive, Convective, and Radiative heat transfer. To impart ideas on heat exchangers, different temperature measurement modules, etc are also the broad objectives of this laboratory. Pictorial views of some of the instruments are shown below:

IC Engine Laboratory

Internal Combustion Engine Laboratory is also well numerous instruments to enhance the knowledge of the students and the instruments are bought with the full financial support of TEQIP-III of the Institute. In this laboratory, cut-sections models of different engines along with VTD plotting are presented to the students. Performance measurement tests on single cylinder diesel, petrol engines, multi-cylinder engines are also being performed in this laboratory.

Along with these above-mentioned test facilities, one multi-fuel VCR engine with open ECU is there in this laboratory for carrying out research activities. Performance, combustion testing can be conduction with the available instruments using different alternative fuels. This laboratory is also well equipped with Multi-gas Analyser to check the emission characteristics from the engine. Pictorial views of some of the instruments are depicted below:

Refrigeration and Air-conditioning Laboratory

The refrigeration & Air-conditioning laboratory is consisting of several instruments to provide hands-on knowledge on the subject. Recently in this laboratory, instruments related to refrigeration experiments are there and they are bought with the financial aid of TEQIP-III of the Institute. Cut-section models of different types of compressors, the domestic refrigerator is shown to the students to impart ideas about different components as well as their working. Determination of COP of domestic type refrigerator, small ice plant (computerized), VAR system is taught to the students. Experimentation on refrigerant leak detection is carried out in this laboratory. Furthermore, the laboratory is also equipped with an AC test rig, a Thermo-electric refrigerator, models of different types of compressors, etc. Pictorial views of some of the instruments are depicted below:

Energy Conversion Laboratory

The energy conversion laboratory of the Institute is well equipped with many state-of-the-art facilities to acquire knowledge about different types of basic energy conversion processes. Cut-section models of different types of boilers are presented to the students in this laboratory. Experimentation on blower test rigs is also carried out in this laboratory. Pictorial views of some of the instruments are depicted below:

Kinematics and Dynamics of Machinery Laboratory

The objectives of Kinematics & Dynamics of Machinery Laboratory are to impart practical knowledge on the design and analysis of mechanisms for the specified type of motion in a machine. With the study of rigid bodies motions and forces for the transmission systems, machine kinematics and dynamics can be well understood. Various experiments with governors, gyroscopes, epicyclic gear trains are available to understand machine dynamics. This laboratory also provides hands-on knowledge on the static and dynamic balancing of a machine component. Pictorial views of some of the instruments are depicted below:

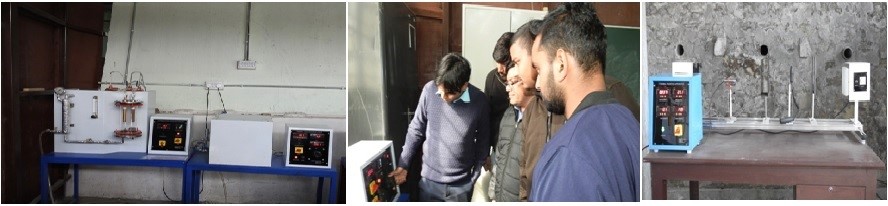

Metal Cutting Laboratory

This course introduces specialized knowledge and skill in machining processes using the principles and methods of engineering analysis, Merchant’s theories of machining. This laboratory is aimed at introducing the Know-how of common processes used in industries for manufacturing parts by removal of material in a controlled manner. Auxiliary devices, as well as methods for machining to desired accuracy and quality, are also covered. The emphasis throughout the laboratory course will be on understanding the basic features of the processes rather than details of constructions of machines, or common practices in manufacturing or acquiring skills in the operation of machines. Pictorial views of some of the instruments are depicted below:

Vibration & Rotor Dynamics Laboratory

The objectives of the vibration and rotor dynamics laboratory are to impart practical knowledge on free and forced vibrations analysis for various types of mechanical components. This laboratory demonstrates the experiments on damping, resonance, and absorber effects in forced vibrations, determination of the oscillation period depending on torsion wire length, diameter, and rotating mass. This laboratory also provides hands-on knowledge on free and damped torsional vibrations. Various experiments with governors, elastic shafts, cam mechanisms are available to understand machine dynamics. Pictorial views of some of the instruments are depicted below: